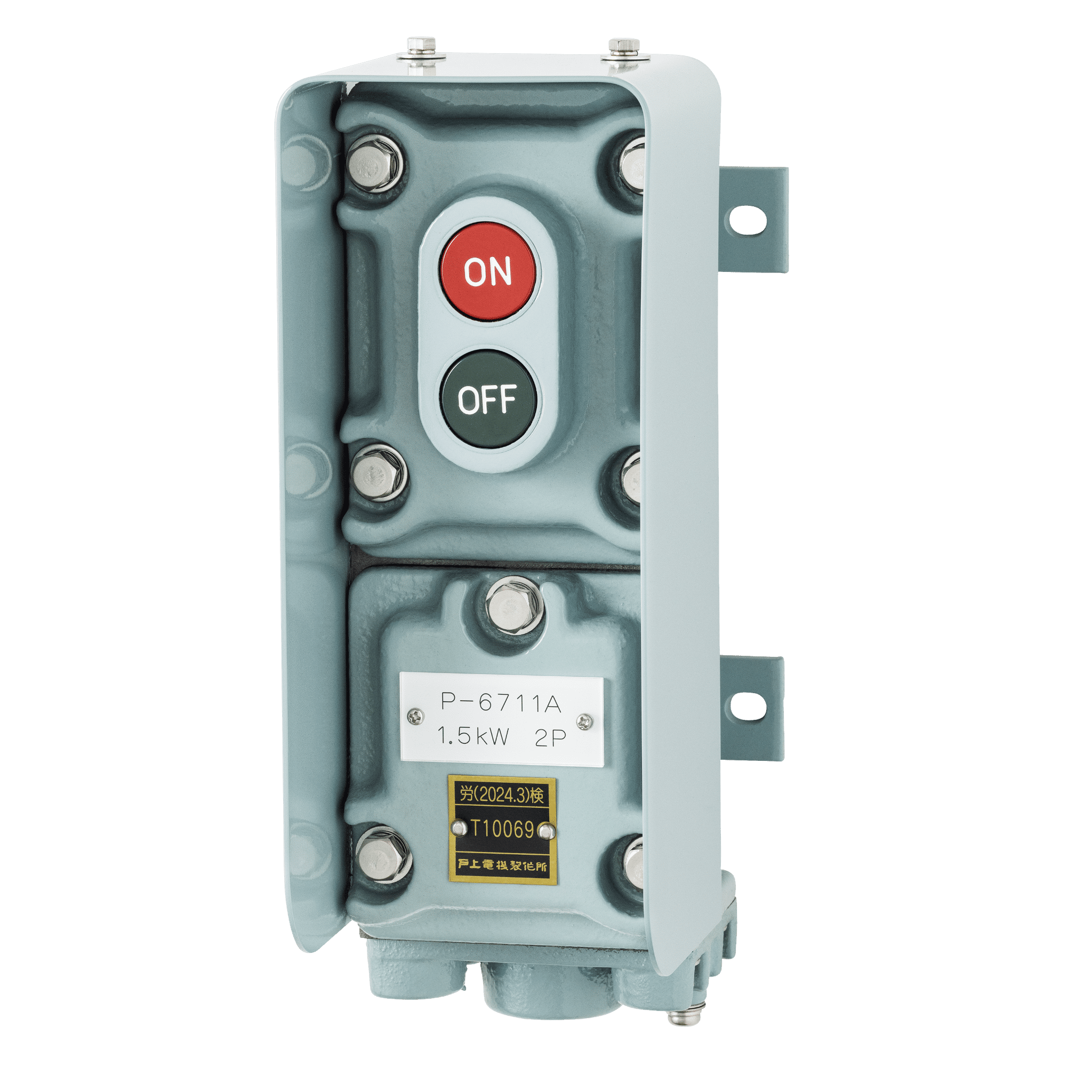

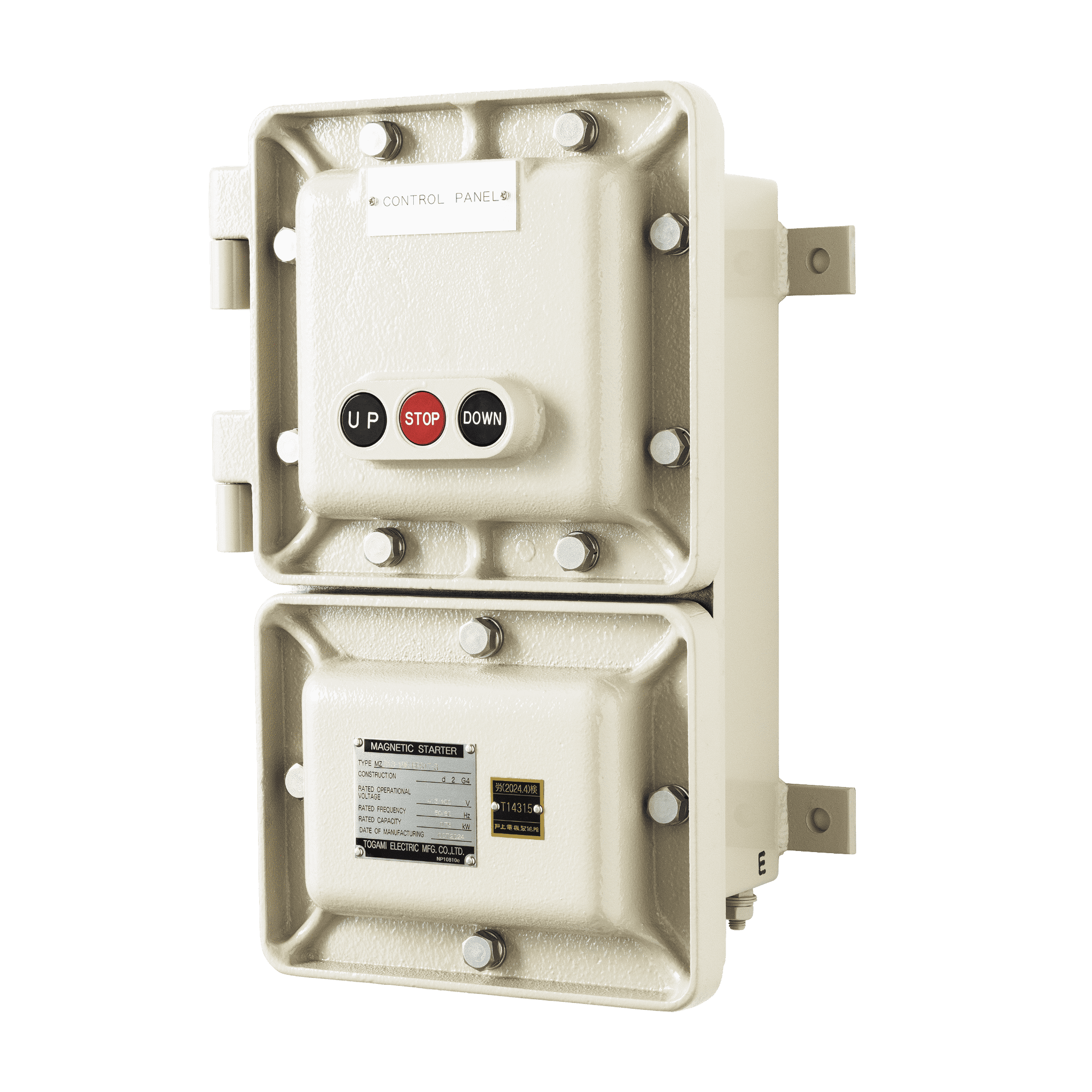

PBZ

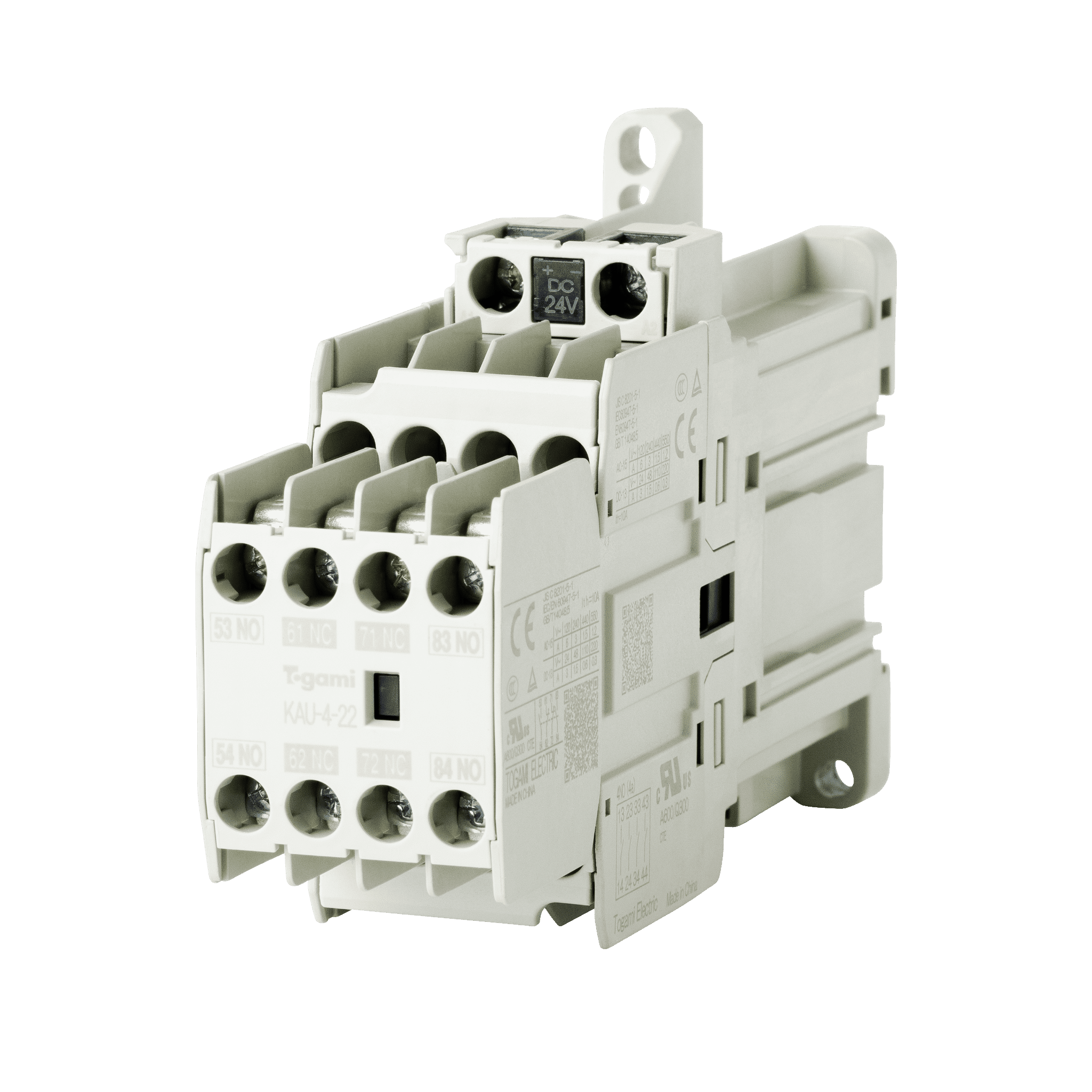

Togami Electric Mfg. manufacturers standard electromagnetic contactor/starters, economical electromagnetic contactor/starters, DC-operated electromagnetic contactor/starters, and other types of electromagnetic contactor/starters.

Our extensive lineup includes PCB relays used for inrush current prevention circuits and pre-charge circuits.

These are units for controlling the switching of equipment, including motors and pumps. They feature a compact design for cost-effectiveness and ease of use, allowing flexible custom designs combining the functions required to meet customer needs.

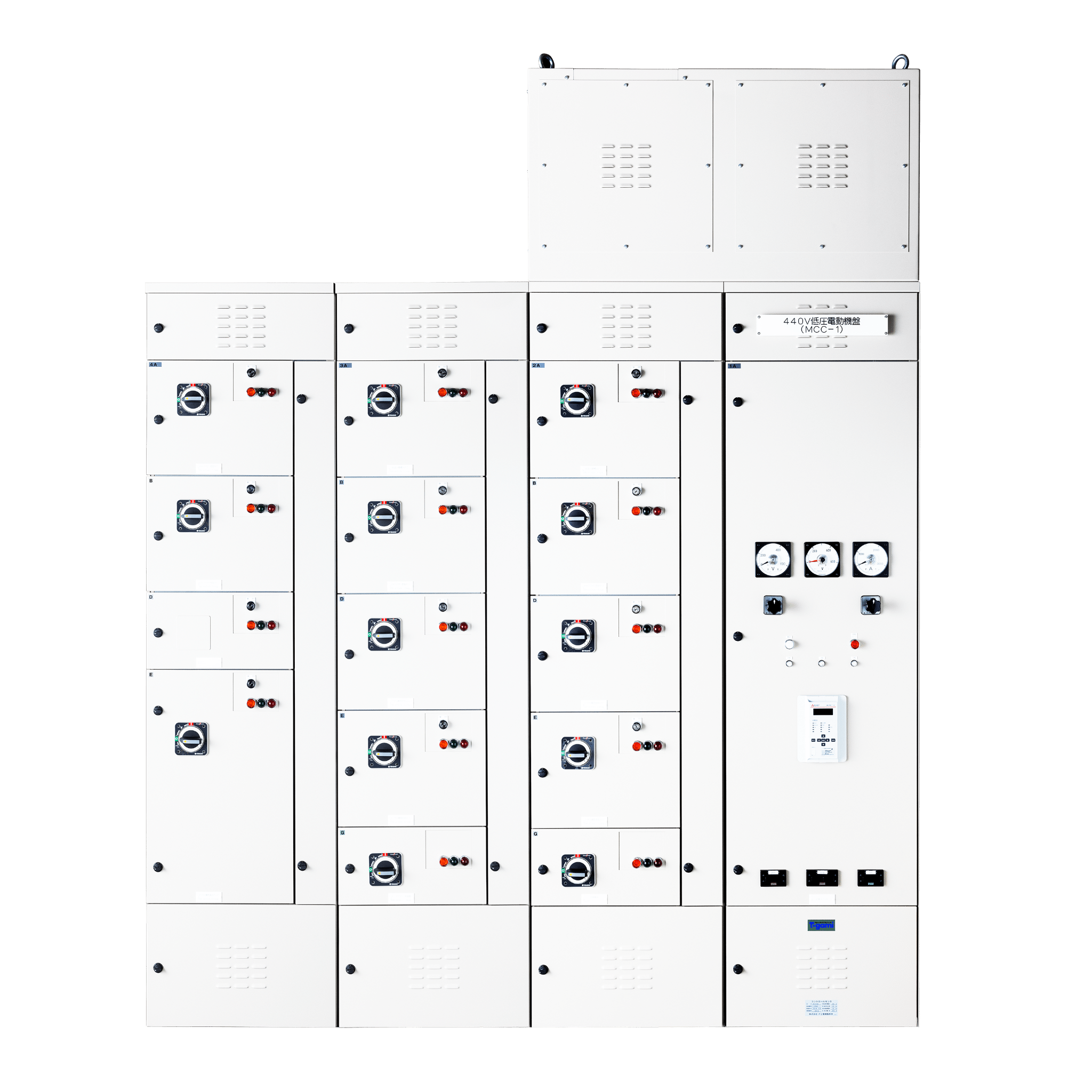

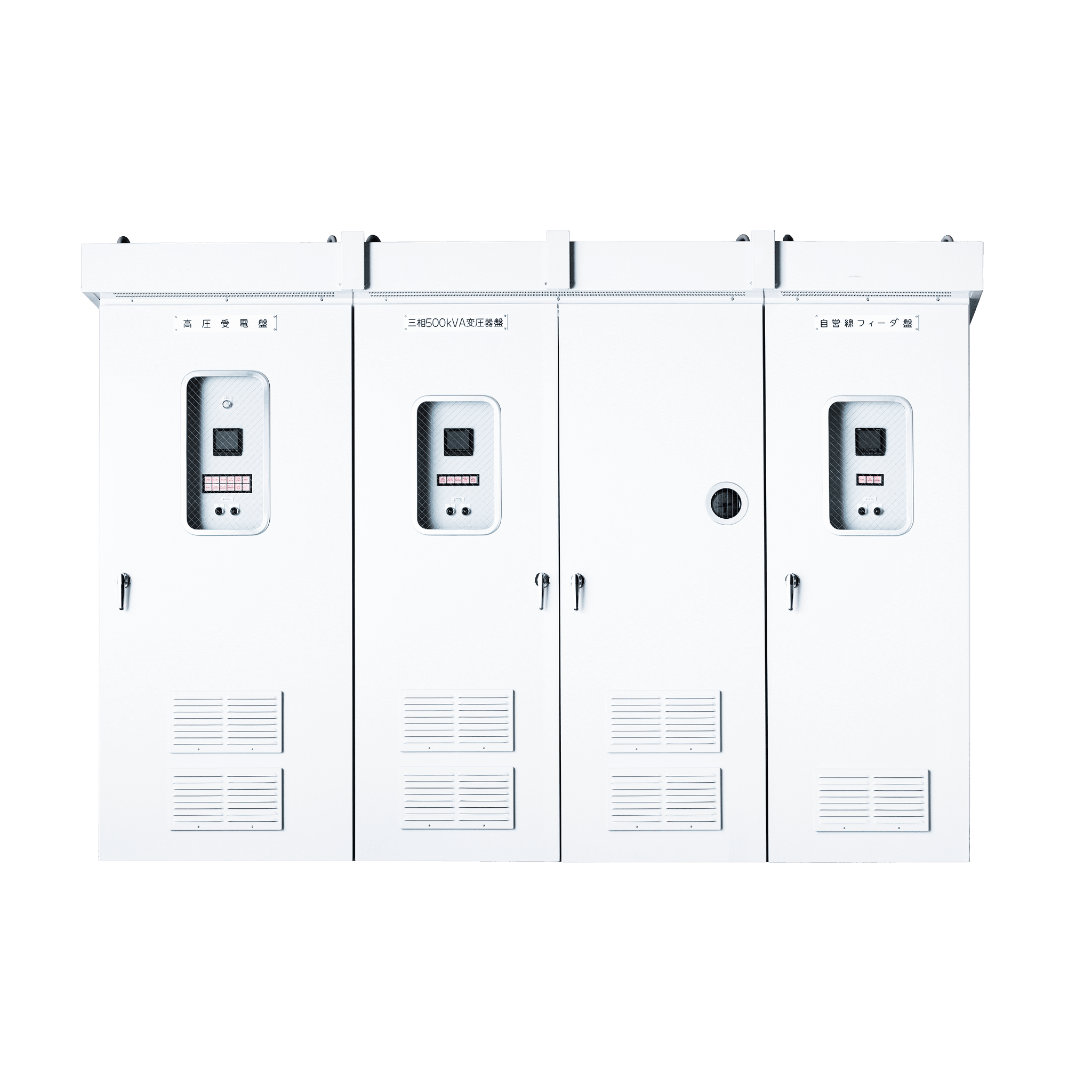

We offer an extensive lineup of different distribution boards, including high-voltage distribution boards. Flexible custom designs are possible by combining those functions required to meet customer needs.

We offer a lineup of explosion-proof control equipment for use in explosion-proof areas, corrosion-resistant control equipment ideal for use in environments where corrosive gases are present.

This is ideal for checking lines following faults or during maintenance before electrical equipment expansion or modification work. It allows live power lines to be checked by a single operator.

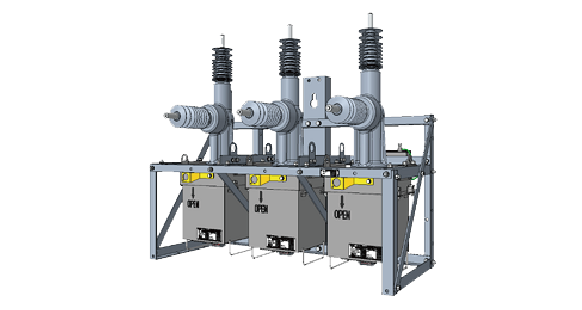

Togami Electric Mfg. Co., Ltd. designs, manufactures, and supplies Automatic Circuit Reclosers (Fault Clear) for power distribution lines.

We manufacture Ring Main Units (RMU) to connect, control, and protect different sections of a ring network.

『Make the society,

the Earth,

and the future prosperous!』

PBZ

CZ

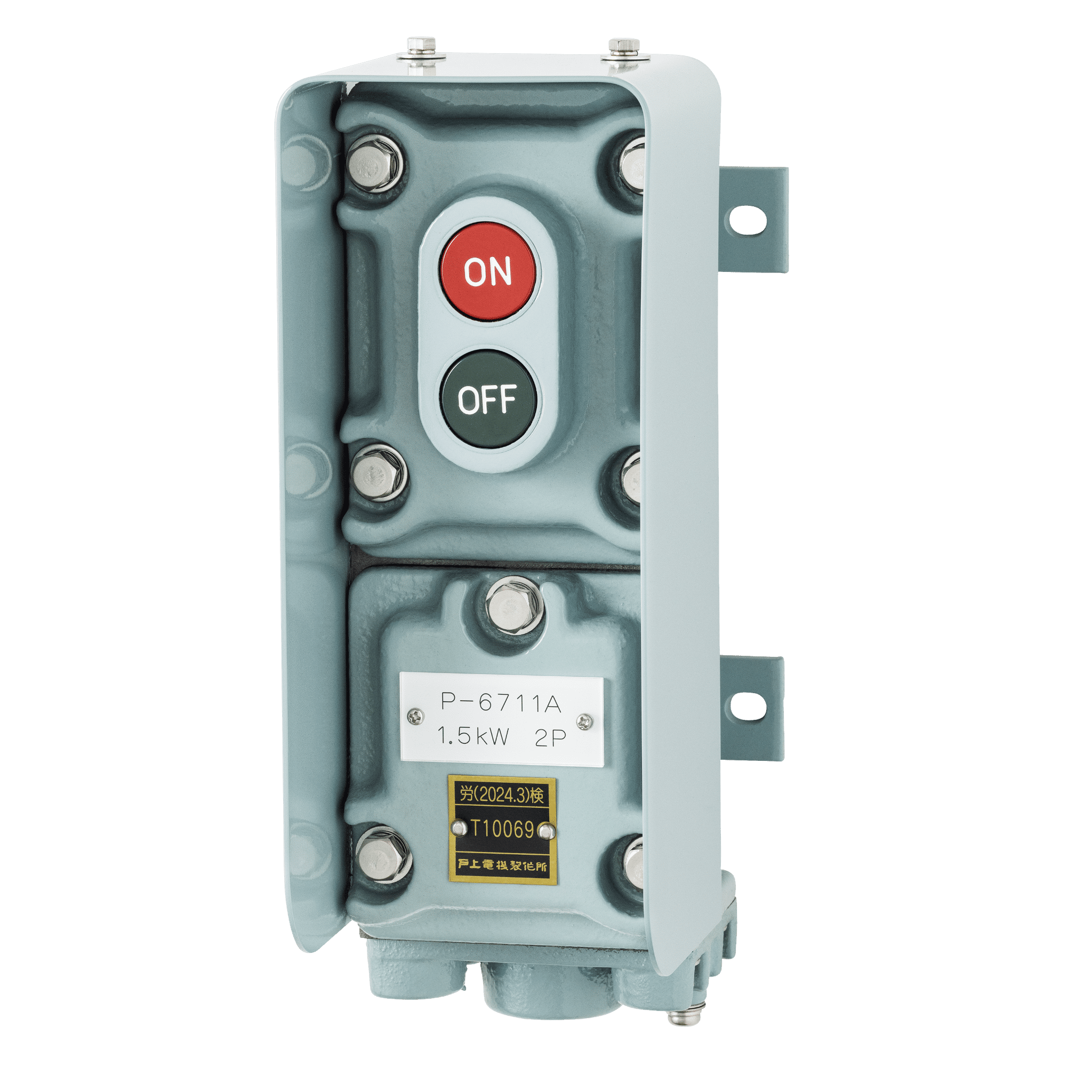

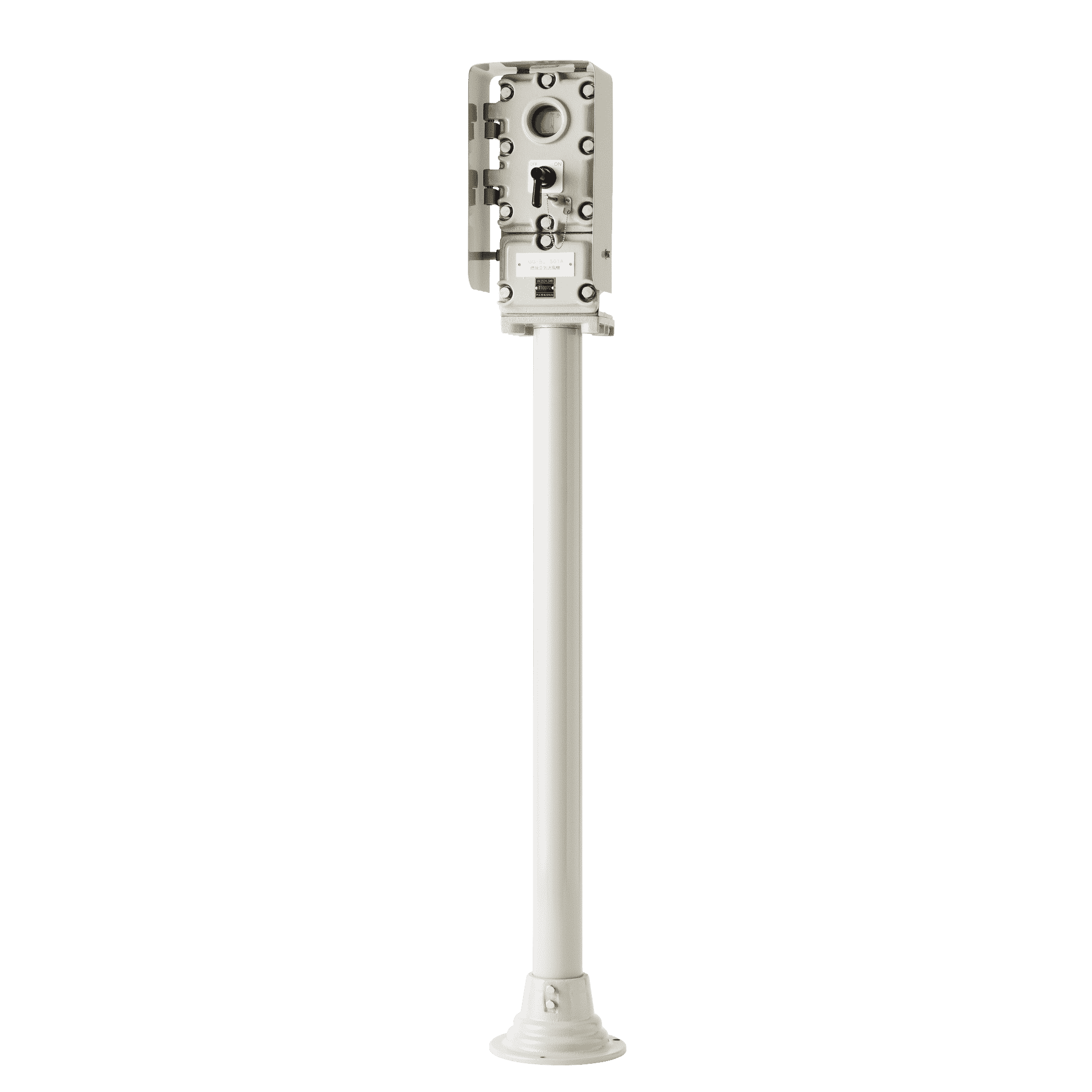

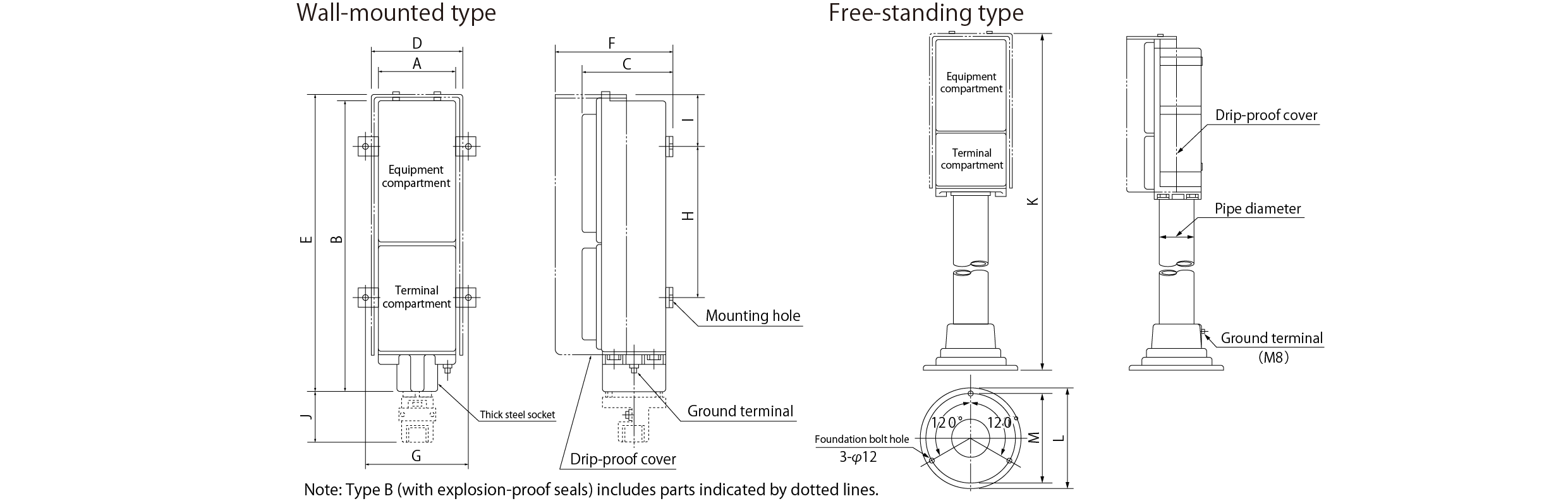

Cast-iron explosion-proof control switches with an explosion protection rating of d2G4※.

※ Electrical Equipment Explosion-Proof Design Standard (Japan)

| Type | Material | Accessories | Hazardous location | Explosion-proof construction |

|---|---|---|---|---|

| CZ | Cast-iron | operating push-button, indicating lamp, changeover switch, ammeter | Applicable in hazardous locations class 1 and 2 | d2G4 |

| PZ | operating push-button, indicating lamp, changeover switch | |||

| PBZ | operating push-button |

| Type | CZ・PZ・PBZ |

|---|---|

| Explosion-proof performance | d2G4 |

| Water-proof performance | Explosion-proof for outdoor(technical guide RⅡS-TR-79-1) |

| Material(case) | Cast-iron (steel plate for exterior dimension drawing No. 18 only) |

| Insulation resistance | More than 5 MΩ(by 500 VDC megger) |

| Standard service condition (technical guide RⅡS-TR-79-1) |

Altitude: Max. 1,000 m Ambient temperature:-10 ℃ to +40 ℃ Relative humidity:45% to 85% |

| Type | CZ(with ammeter) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Dimensions No. | Dwg.3 | Dwg.4 | Dwg.8 | Dwg.9 | Dwg.13 | Dwg.14 | Dwg.15 | Dwg.16 | Dwg.17 | Dwg.18 | ||

| Wall mounting type(D・B) | without drip-proof cover | A | 100 | 154 | 232 | 302 | ||||||

| B | 384.5 (362.5) |

378(356) | 418(396) | 504(493) | 546 | |||||||

| C | 109 | 132 | 172 | 224 | ||||||||

| with drip-proof cover | D | 106 | 173 | 195 | 275 | 375 | ||||||

| E | 389 (367) |

387(365) | 427(405) | 512(501) | 555 | |||||||

| F | 160 | 176 | 236 | 275 | ||||||||

| Mounting | G | 120 | 154 | 220 | 270 | |||||||

| H | 200 | 230 | 270 | 250 | 350 | |||||||

| I | 67 | 54 | 61 | 98 | 97 | |||||||

| Mounting holes | 4-φ9 | 4-φ14 | ||||||||||

| Explosion-proof seal seating groove J | Max.67 | Max.65 | Max.85 | Max.90 | ||||||||

| Heavy gauge steel socket | Max.36×1 | Max.36×2 | Max.36×2、28×3 | Max.36×3 | ||||||||

| Earth terminal | M6 | M8 | ||||||||||

| Cover retaining bolts | M8 | M10 | M12 | |||||||||

| Weight(kg) | 11 | 19 | 20 | 29 | 30 | 45 | ||||||

| Standing type(E・K) | K | 1500 | ||||||||||

| Mounting frame | L | φ210 | φ220 | |||||||||

| M | φ190 | φ200 | ||||||||||

| Pipe diameter | 1 1/2 | 2 1/2 | 3 | 3B | ||||||||

| Weight(kg) | 15 | 28 | 29 | 43 | 44 | 60 | ||||||

| Type | PZ(without ammeter) | PBZ(operating push button) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Dimensions No. | Dwg.5 | Dwg.6 | Dwg.7 | Dwg.10 | Dwg.11 | Dwg.12 | Dwg.1 | Dwg.2 | ||

| Wall mounting type(D・B) | without drip-proof cover | A | 154 | 232 | 100 | |||||

| B | 378(356) | 418(396) | 504(493) | 300.5(278.5) | 384.5(362.5) | |||||

| C | 132 | 172 | 114 | 109 | ||||||

| with drip-proof cover | D | 173 | 195 | 275 | 106 | |||||

| E | 387(365) | 427(405) | 512(501) | 309.5(287.5) | 389(367) | |||||

| F | 176 | 236 | 165 | 160 | ||||||

| Mounting | G | 154 | 220 | 100 | 120 | |||||

| H | 230 | 270 | 250 | 150 | 200 | |||||

| I | 54 | 61 | 98 | 55 | 67 | |||||

| Mounting holes | 4-φ9 | |||||||||

| Explosion-proof seal seating groove J | Max.65 | Max.85 | Max.67 | |||||||

| Heavy gauge steel socket | Max.36×2 | Max.36×2、28×3 | Max.36×1 | |||||||

| Earth terminal | M6 | |||||||||

| Cover retaining bolts | M10 | M12 | M8 | |||||||

| Weight(kg) | 19 | 20 | 29 | 8 | 11 | |||||

| Standing type(E・K) | K | 1500 | 1000 | 1500 | ||||||

| Mounting frame | L | φ210 | φ220 | φ135 | φ210 | |||||

| M | φ190 | φ200 | φ110 | φ190 | ||||||

| Pipe diameter | 2 1/2 | 3 | 1 1/2 | |||||||

| Weight(kg) | 28 | 29 | 43 | 12 | 15 | |||||

| Ammeter | 60 mm square, 3-times scale, with a red pointer /A or /5 A with CT rate (But, it's direct retirement possible to 30 A.) |

|

|---|---|---|

| Push-button switch | Rated current | 10 A |

| Operating current | 220 VAC-5 A 110 VDC-1.2 A(lagging load) |

|

| Color | Red(on)-Green(off) | |

| Letter | ON-OFF | |

| Contact | 1NO-1NC 1NO-1NC | |

| Handle-type operating switches |

Notch | 3 |

| Rated current | 10 A | |

| Operating current | 220 V,5 AAC 110 VDC,1.2 A(lagging load) |

|

| Color | Black | |

| Letter | ON-OFF | |

| Contact | 1NO-1NC 1NO-1NO | |

| Changeover switch | Notch | Specified by customer |

| Rated current | 10 A | |

| Operating current | 220 VAC,5 A 110 VDC,1.3 A(lagging load) |

|

| Color | Black | |

| Contact | Specified by customer | |

| Indicating lamp | Bulb | Incandescent lamp with transformer |

| Color | Red, green, orange | |

| Voltage | 100 VAC,200 VAC,110 VAC,220 VAC, 100 VDC,200 VDC,110 VDC,220 VDC |

|

| Painting color | Internal and external surfaces of enclosures: Munsell No.7.5BG6/1.5 | |

| Classfication | Type | Dimensions | Wiring No. | Accessories | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| D (Wall mounting conduit leading) |

B (Wall mounting packing leading) |

E (Stand packing leading) |

K (Stand sealing leading) |

Operating switch | Ammeter | Indicating lamp | Changeover switch | |||

| Control switch | CZD-P011 | CZB-P011 | CZE-P011 | CZK-P011 | Dwg.3 | W30748 | ○ | ○ | ー | ー |

| 〃-P020 | 〃-P020 | 〃-P020 | 〃-P020 | Dwg.3 | W30749 | ○ | ○ | ー | ー | |

| 〃-N011 | 〃-N011 | 〃-N011 | 〃-N011 | Dwg.4 | W30748 | ○ | ○ | ー | ー | |

| 〃-N020 | 〃-N020 | 〃-N020 | 〃-N020 | Dwg.4 | W30749 | ○ | ○ | ー | ー | |

| 〃-N111 | 〃-N111 | 〃-N111 | 〃-N111 | Dwg.8 | W31303 | ○ | ○ | RL | ー | |

| 〃-N120 | 〃-N120 | 〃-N120 | 〃-N120 | Dwg.8 | W31304 | ○ | ○ | 〃 | ー | |

| 〃-N211 | 〃-N211 | 〃-N211 | 〃-N211 | Dwg.8 | W30759 | ○ | ○ | GL.RL | ー | |

| 〃-N220 | 〃-N220 | 〃-N220 | 〃-N220 | Dwg.8 | W31300 | ○ | ○ | 〃 | ー | |

| 〃-NH011 | 〃-NH011 | 〃-NH011 | 〃-NH011 | Dwg.9 | W31309 | ○ | ○ | ー | ー | |

| 〃-NH020 | 〃-NH020 | 〃-NH020 | 〃-NH020 | Dwg.9 | W31310 | ○ | ○ | ー | ー | |

| 〃-QH111 | 〃-QH111 | 〃-QH111 | 〃-QH111 | Dwg.13 | W31341 | ○ | ○ | RL | ー | |

| 〃-QH120 | 〃-QH120 | 〃-QH120 | 〃-QH120 | Dwg.13 | W31342 | ○ | ○ | 〃 | ー | |

| 〃-QH211 | 〃-QH211 | 〃-QH211 | 〃-QH211 | Dwg.13 | W31311 | ○ | ○ | GL.RL | ー | |

| 〃-QH220 | 〃-QH220 | 〃-QH220 | 〃-QH220 | Dwg.13 | W31312 | ○ | ○ | 〃 | ー | |

| 〃-QH311 | 〃-QH311 | 〃-QH311 | 〃-QH311 | Dwg.13 | W31352 | ○ | ○ | GL.OL.RL | ー | |

| 〃-QH320 | 〃-QH320 | 〃-QH320 | 〃-QH320 | Dwg.13 | W31353 | ○ | ○ | 〃 | ー | |

| 〃-Q011G | 〃-Q011G | 〃-Q011G | 〃-Q011G | Dwg.14 | W31319-1 W31319-2 W31319-3 |

○ | ○ | ー | ○ | |

| 〃-Q020G | 〃-Q020G | 〃-Q020G | 〃-Q020G | Dwg.14 | W31320-1 W31320-2 W31320-3 |

○ | ○ | ー | ○ | |

| 〃-Q021 | 〃-Q021 | 〃-Q021 | 〃-Q021 | Dwg.15 | W30750 | ○ | ○ | ー | ー | |

| 〃-Q121 | 〃-Q121 | 〃-Q121 | 〃-Q121 | Dwg.16 | W31340 | ○ | ○ | RL | ー | |

| 〃-Q221 | 〃-Q221 | 〃-Q221 | 〃-Q221 | Dwg.16 | W30756 | ○ | ○ | GL.RL | ー | |

| 〃-Q321 | 〃-Q321 | 〃-Q321 | 〃-Q321 | Dwg.16 | W31337 | ○ | ○ | GL.OL.RL | ー | |

| 〃-Q311 | 〃-Q311 | 〃-Q311 | 〃-Q311 | Dwg.16 | W31338 | ○ | ○ | 〃 | ー | |

| 〃-Q320 | 〃-Q320 | 〃-Q320 | 〃-Q320 | Dwg.16 | W31339 | ○ | ○ | 〃 | ー | |

| 〃-QH311G | 〃-QH311G | 〃-QH311G | 〃-QH311G | Dwg.17 | W31354-1 W31354-2 W31354-3 |

○ | ○ | 〃 | ○ | |

| 〃-QH320G | 〃-QH320G | 〃-QH320G | 〃-QH320G | Dwg.17 | W31355-1 W31355-2 W31355-3 |

○ | ○ | 〃 | ○ | |

| 〃-QH211G | 〃-QH211G | 〃-QH211G | 〃-QH211G | Dwg.17 | W31356-1 W31356-2 W31356-3 |

○ | ○ | GL.RL | ○ | |

| 〃-QH220G | 〃-QH220G | 〃-QH220G | 〃-QH220G | Dwg.17 | W31357-1 W31357-2 W31357-3 |

○ | ○ | 〃 | ○ | |

| 〃-QH111G | 〃-QH111G | 〃-QH111G | 〃-QH111G | Dwg.17 | W31358-1 W31358-2 W31358-3 |

○ | ○ | RL | ○ | |

| 〃-QH120G | 〃-QH120G | 〃-QH120G | 〃-QH120G | Dwg.17 | W31359-1 W31359-2 W31359-3 |

○ | ○ | 〃 | ○ | |

| 〃-N111G | 〃-N111G | 〃-N111G | 〃-N111G | Dwg.18 | W31334-1 W31334-2 W31334-3 |

○ | ○ | 〃 | ○ | |

| 〃-N120G | 〃-N120G | 〃-N120G | 〃-N120G | Dwg.18 | W31335-1 W31335-2 W31335-3 |

○ | ○ | 〃 | ○ | |

| 〃-N211G | 〃-N211G | 〃-N211G | 〃-N211G | Dwg.18 | W31327-1 W31327-2 W31327-3 |

○ | ○ | GL.RL | ○ | |

| 〃-N220G | 〃-N220G | 〃-N220G | 〃-N220G | Dwg.18 | W31328-1 W31328-2 W31328-3 |

○ | ○ | 〃 | ○ | |

| 〃-N311G | 〃-N311G | 〃-N311G | 〃-N311G | Dwg.18 | W31344-1 W31344-2 W31344-3 |

○ | ○ | GL.OL.RL | ○ | |

| 〃-N321G | 〃-N321G | 〃-N321G | 〃-N321G | Dwg.18 | W31336-1 W31336-2 W31336-3 |

○ | ○ | 〃 | ○ | |

| Classfication | Type | Dimensions | Wiring No. | Accessories | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| D (Wall mounting conduit leading) |

B (Wall mounting packing leading) |

E (Stand packing leading) |

K (Stand sealing leading) |

Operating switch | Ammeter | Indicating lamp | Changeover switch | |||

| Push-button switch | PBZD-N10 | PBZB-N10 | PBZE-N10 | PBZK-N10 | Dwg.1 | W31346 | ○ | ー | ー | ー |

| 〃-N01 | 〃-N01 | 〃-N01 | 〃-N01 | Dwg.1 | W31347 | ○ | ー | ー | ー | |

| 〃-N11 | 〃-N11 | 〃-N11 | 〃-N11 | Dwg.1 | W30730 | ○ | ー | ー | ー | |

| 〃-N20 | 〃-N20 | 〃-N20 | 〃-N20 | Dwg.1 | W30731 | ○ | ー | ー | ー | |

| 〃-N21 | 〃-N21 | 〃-N21 | 〃-N21 | Dwg.2 | W31302 | ○ | ー | ー | ー | |

| Control switch | PZD-N111 | PZB-N111 | PZE-N111 | PZK-N111 | Dwg.5 | W31307 | ○ | ー | RL | ー |

| 〃-N120 | 〃-N120 | 〃-N120 | 〃-N120 | Dwg.5 | W31308 | ○ | ー | 〃 | ー | |

| 〃-N211 | 〃-N211 | 〃-N211 | 〃-N211 | Dwg.5 | W30735 | ○ | ー | GL.RL | ー | |

| 〃-N220 | 〃-N220 | 〃-N220 | 〃-N220 | Dwg.5 | W30737 | ○ | ー | 〃 | ー | |

| 〃-NH111 | 〃-NH111 | 〃-NH111 | - | Dwg.6 | W31315 | ○ | ー | RL | ー | |

| 〃-NH120 | 〃-NH120 | 〃-NH120 | Dwg.6 | W31316 | ○ | ー | 〃 | ー | ||

| 〃-NH211 | 〃-NH211 | 〃-NH211 | Dwg.6 | W31317 | ○ | ー | GL.RL | ー | ||

| 〃-NH220 | 〃-NH220 | 〃-NH220 | Dwg.6 | W31318 | ○ | ー | 〃 | ー | ||

| 〃-N011G | 〃-N011G | 〃-N011G | PZK-N011G | Dwg.7 | W31321-1 W31321-2 W31321-3 |

○ | ー | ー | ○ | |

| 〃-N020G | 〃-N020G | 〃-N020G | 〃-N020G | Dwg.7 | W31322-1 W31322-2 W31322-3 |

○ | ー | ー | ○ | |

| 〃-N111G | 〃-N111G | 〃-N111G | - | Dwg.10 | W31323-1 W31323-2 W31323-3 |

○ | ー | RL | ○ | |

| 〃-N120G | 〃-N120G | 〃-N120G | Dwg.10 | W31324-1 W31324-2 W31324-3 |

○ | ー | 〃 | ○ | ||

| 〃-N211G | 〃-N211G | 〃-N211G | Dwg.10 | W31325-1 W31325-2 W31325-3 |

○ | ー | GL.RL | ○ | ||

| 〃-N220G | 〃-N220G | 〃-N220G | Dwg.10 | W31326-1 W31326-2 W31326-3 |

○ | ー | 〃 | ○ | ||

| 〃-Q321 | 〃-Q321 | 〃-Q321 | PZK-Q321 | Dwg.11 | W31343 | ○ | ー | GL.OL.RL | ー | |

| 〃-Q221 | 〃-Q221 | 〃-Q221 | 〃-Q221 | Dwg.11 | W31332 | ○ | ー | GL.RL | ー | |

| 〃-Q121 | 〃-Q121 | 〃-Q121 | 〃-Q121 | Dwg.11 | W31349 | ○ | ー | RL | ー | |

| 〃-Q311 | 〃-Q311 | 〃-Q311 | 〃-Q311 | Dwg.12 | W31350 | ○ | ー | GL.OL.RL | ー | |

| 〃-Q320 | 〃-Q320 | 〃-Q320 | 〃-Q320 | Dwg.12 | W31351 | ○ | ー | 〃 | ー | |

・Wiring, operation, maintenance, and inspections of these products must be performed by personnel with specialized knowledge and skills in the installation of explosion-proof electrical equipment and related regulations.

・For installations in hazardous locations, please check the applicable hazardous area classification. The hazardous areas in which products may be installed will vary depending on the specific model.

・Please note that specfications, dimensions, etc., are subject to change without prior notice.

Prior to installed of explosion-proof electrical equipments, careful study should be made on the following recommendations.

1. To prevent explosions or files caused by the electrical equipments, every effort should be made, as a prerequisite, to minimize possible danger of explosion at a location where they are to be installed.

2. The electrical equipments should be installed at a location with a minimum posibility of explosion. In case, however, they are unavoidably installed at a hazardous location where explosion is expected, it should be limited to a minimum extent.

3. The explosion-proof electrical equipments to be installed should be the products that have been proved to fully meet he requirements.

Study the sorts of inflammable gas or steam present at a location where the electrical equipments are to be installed in order to determine the explosion class and the firing degree. Then, determine the hazardous locations according to the degree of danger of the locations where the electrical equipments are to be installed. The explosion-proof electrical equipments may be selected on the basis of the determination of explosion class, firing degree and hazardous locations.

The danger class of explosive gas is determined by the firing degree and explosion class.

| Firing degree | Firing point |

|---|---|

| G1 G2 G3 G4 G5 |

over 450 ℃ over 300 ℃ up to 450 ℃ over 200 ℃ up to 300 ℃ over 135 ℃ up to 200 ℃ over 100 ℃ up to 135 ℃ |

| Explosion class | Minimum clearance which permits flame running at 25 mm. |

|---|---|

| 1 2 3 |

over 0.6 mm over 0.4 mm up to 0.6 mm up to 0.4 mm |

| G1 | G2 | G3 | G4 | G5 | |

|---|---|---|---|---|---|

| 1 | Ammonia Carbon monoxide Acetic acid Propane Methane |

Ethanole Amyl Acetate-iso 1-Buthanole Butane Acetic anhydride |

Gasoline Hexane |

Acetaldehyde Ethylether |

|

| 2 | Coal gas | Ethylene Ethylene oxide |

|||

| 3 | Water gas Hydrogen |

Acetylene |

The areas of possible danger or to be dangerous atmosphere are classfield into class 0, class 1 and class 2 depending upon the dangerous time and frequency of occurrence of danger.

Class 0・・・Where dangerous density of explosive gas continues or is held for a long time above the lower limit of an explosion.

Class 1・・・Where a dangerous atmosphere is expected to be present under normal state.

Class 2・・・Where a dangerous atmosphere is expected to be present under abnormal state.

The explosion-proof construction is designed to protect the equipment in use at a hazardous location and can be divided into many different types including pressure-resisting explosion-proof(d), oil-immersed explosion-proof(o), internal pressure-resisting explosion-proof(f), increased safety explosion-proof(e), substantial safety explosion-proof(i), special explosion-proof(s) and other varying types. Out of them, the following construction types are employed in the explosion-proof electrical equipment introduced in this paper.

※ Pressure-resisting explosion-proof type(d)

This is of a totally enclosed construction, and should an explosion take place inside the enclosure, the enclosure resists the resultant pressure eliminating a danger of igniting an explosive gas outside.

※ Increased safety explosion-proof type(e)

This is of the construction which is particularly provided with increased safety on its construction or temperature rise, in order to prevent sparking arcing and overheating on those parts which should not essentially generate them.